About Us

Thanks to our 20 years of industry experience, 4000+ customer references and our services understanding conducted in accordance with ISO 9001 quality management standard, we are the preference of the very best.

What We Produce

// QUALITY ECONOMIC INDUSTRY SPECIFIC

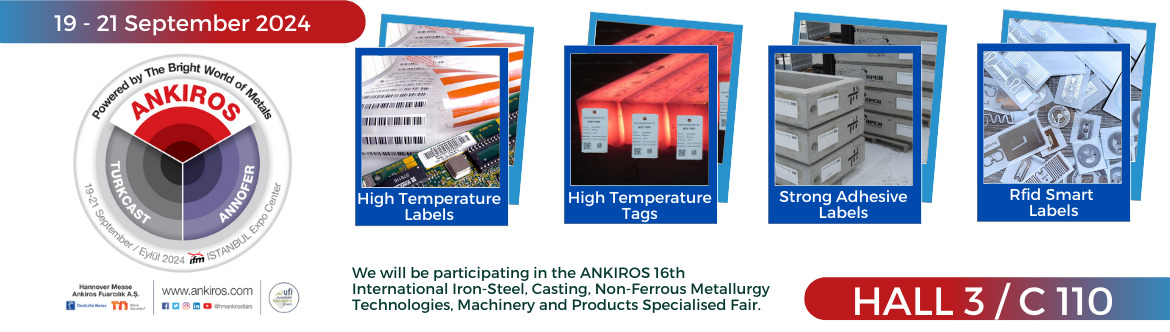

RFID Label Production

With our Rfid Application Machine, we apply UHF, HF, NFC chips to Labels that meet the demands of our customers (Size, Surface and Adhesive). We produce Rfid Tags that are company specific; they can be printed, blank or contain variable data.

Printed and Blank Label Production

We offer Printed Labels, Blank Labels and Variable Numerator printed labels to our customers with the highest quality raw materials in the world. We not only produce labels, but also offer solutions.

Thermal Transfer Ribbon Converting

We cut thermal transfer ribbons imported from Europe to the desired sizes for Barcode Printer and Date coding applications. Our ribbons meet the expectations of the sectors that want specific solutions such as hot, cold, scratch and chemical resistance at the highest level.

Lamination and Coating Line

With our Laminating and Coating machine, we make an acrylic-based adhesive version with a width of 114 cm and a silicone coating. We produce special label raw materials according to the needs of our customers by laminating acrylic adhesive options on different top surfaces (Paper, PP, PET, etc.).

Solutions by Industry

// CUSTOMER AND INNOVATION FOCUSED

Labels are used in different industries for different applications. The most accurate label is not the most affordable or best adhering label, but the one that performs the best “in your application and industry”. For example, a strong adhesion is required on a tire label, but the label that sticks to glass should be easily removed and leave no mark. Every industry has different expectations. Egen Barcode produces dozens of applications and industry-specific solutions with this understanding.

Labels

Barcode labels can also be used as non-adhesive, hang tags, but the most commonly used barcode labels are self-adhesive. Adhesive labels are mainly composed of three layers: facestock + adhesive + bottom liner. The facestock can be paper ( thermal, coated, etc.), film, (PP, PE, PET, HDPE). Adhesive types vary from hotmelt, acrylic, deep freeze, rubber, non-perm, silicone, strong rubber hotmelt (referred to as tyre adhesive). According to the need of the application, such as heat, pressure, external conditions, etc., these adhesives are divided into subclasses. The bottom liner, on the other hand, can be silicone paper of different weights or PET film for breakage resistance.

RFID Tags

RFID tags are used in dozens of industries for tracking (movement, heat, etc.), asset and inventory tracking or information purposes. RFID tags consist of three parts: microchip (stores and processes information), antenna (modulates/demodulates RF signals) and substrate. They are also divided into three according to their frequency ranges. HF (High Frequency) , UHF (Ultra High Frequency) , NFC (Near Field Communication) . RFID chips can be embedded under different label materials and used w,th adhesive, as well as types of Hard Tags that can be embedded in the material that can be used by hanging without adhesive in environments where difficult conditions are required.

Hardware

Our hardware product line includes RFID label printer, barcode label printer and color inkjet printers. RFID tag printers print on labels with an RFID chip integrated into them. Barcode printers, on the other hand, perform thermal transfer or direct thermal printing. They are divided into desktop or industrial. With the thermal transfer method, using ribbon, you can print black or monochrome red,blue, green. Direct thermal printers are available for direct thermal printing on thermal paper or film without using a ribbon. Your preference for color CMYK labels should be in favor of color inkjet printers.