- Structure : Polyamide Film

- Temperature Resistance: 260 0 C

- Total Thickness: 143 Micron

- Surface Weight: 75 gr/m2

- Surface Thickness: 46 Micron

- Adhesive Type : Solvent Acrylic

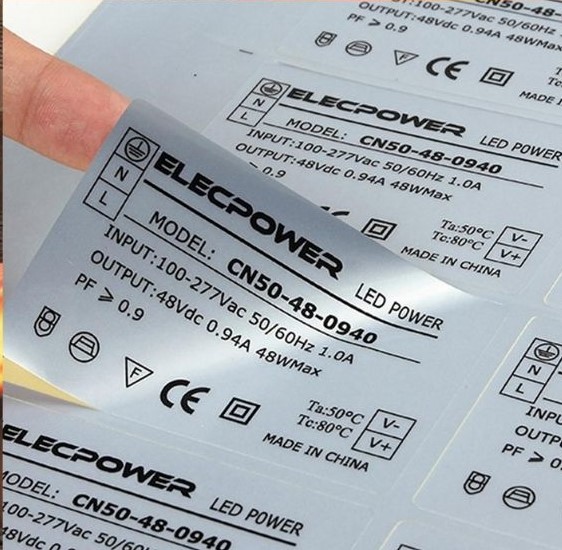

Polyamide Label (6060)

The surface of the polyamide 6060 adhesive label is specially coated for thermal transfer printing, the adhesive and the top surface film are specially formulated to withstand high temperatures.

Applicable to all soldering operations on the market but not recommended for wave soldering applications applied to the underside of the PCB

Depending on the conditions, it can withstand peak temperatures up to +300°C without discoloration, without losing its adhesion strength. If used with suitable thermal transfer ribbons, it is resistant to friction, high temperature and solvents.

High strength polyamide film, high opacity, semi-gloss white Maximum temperature resistance 260 0 C.

It must be tested before definitive application.

- Structure : Aluminum Film

- Tempera resistance: 500 0 C

- Total Thickness: 210 Micron

- Surface Weight: 210 gr/m2

- Surface Thickness: 150 Micron

- Adhesive Type : Sensitive Acrylic

Aluminum Label (6050)

6050 Aluminum label with permanent pressure sensitive acrylic adhesive and specially coated for thermal transfer printing.

The 6050 Aluminum label is designed for barcode or alphanumeric identification of metal items with temperatures up to 932 F or 500° C. It is the ideal label to withstand the high temperatures encountered in quenching, rolling and other processes. It retains its adhesive even when the product and label are removed directly from a hot environment.

The 6050 Aluminum label can be used with most industrial thermal transfer printers, but the correct ribbon must be selected.

- Structure : PET Film

- Temperature resistance: 120 0 C

- Total Thickness: 142 Micron

- Top Surface Weight: 71 gr/m2

- Surface Thickness: 50 Micron

- Adhesive Type : Permanent Hotmelt

PET -PT Label (3050)

PET Film 3050 label has been specially treated on the upper surface to provide excellent ink absorption.

The product is primarily for use in "durable" applications that require heat and solvent resistance. The product is also suitable for use in 'graphics'.

Thanks to the aggressive structure of the adhesive; it shows high performance on rough or difficult surfaces such as rubber, shoes, rugs, carpets, cardboard, wood, fiber drums and plastic (eg HDPE and Polypropylene drums).

If it is printed by resin ribbon , the print quality is high and resistant to abrasion.

- Structure : PET Matt Chrome Film

- Temperature resistance: 120 0 C

- Total Thickness: 120 Micron

- Surface Weight: 59 gr/m2

- Surface Thickness: 50 Micron

- Adhesive Type : Permanent Acrylic

PET Matt Silver Label (3030)

The upper surface of the 3030 label is a PET Matte Chrome film. It is suitable for applications that require high temperature and it is resistant to chemicals. The upper surface is very good in printing. It gives successful results in rubbing tests. Its color is silver matt.

It is used in industries that need durable labels such as iron and steel rolling, manufacturing, chemistry, energy, computers, automotive, heating and cooling.

The adhesive is suitable for smooth surfaces (eg ABS, Polystirene, Polycarbonate and Nylon.) with high or medium surface energy such as metals or plastics.

Common uses are labels for identification, inventory, and logistics.

Suitable for thermal transfer printing. It is recommended to use resin ribbon for scratch resistance.

- Structure : Polypropylene Film

- Temperature resistance: 70 0 C

- Total Thickness: 189 Micron

- Surface Weight: 45 gr/m2

- Surface Thickness: 60 Micron

- Adhesive Type : Aggressive tire hotmelt

5150 PP Film Tire Label (5150)

5150 PP Film Tire Label is from the plastic-based label group. It is bright white in color, highly resistant to water, tearing and outdoor conditions.

Polypropylene does not stretch and does not tear easily as long as it is not forced. In this way, it is suitable for use in outdoor environments.

The 5150 label is long-lasting and has a wide range of uses. Applications are mainly on hard surfaces such as Glass, PET. Due to its hard structure, care should be taken to use it on uneven surfaces.

The adhesive is specific to automotive tire labeling requirements. Penetrates the ribbed and curved tire structure and secures the label. Resistant to surface contaminants. Due to this aggressive structure in the adhesive; so that adhesive does not bleed from the edges; special care must be taken in cutting, printing and storage.

It can be produced as printed, and after it is produced, it can be printed with barcode printers using ribbon

- Structure: Polypropylene Film

- Heat resistance: 70 0 C

- Total Thickness: 150 Micron

- Surface Weight: 43 gr/m2

- Surface Thickness: 58 Micron

- Adhesive Type : Tyre hotmelt

PP Film Tyre Label (5200)

5200 PP Film Tire Label is from the plastic-based label group. It is bright white in color. It is highly resistant to water, tearing and outdoor conditions. Polypropylene does not stretch and does not tear easily as long as it is not forced. In this way, it is suitable for use in outdoor environments.

It is long-lasting and its usage areas are quite wide. Applications are mainly on hard surfaces such as Glass, PET. Due to its hard structure, care should be taken to use the label on uneven surfaces.

Aggressive structure of the adhesive, it shows high performance on rubber, shoes, rugs, carpets, packaging, materials such as cardboard, wood, fiber drums and plastic (eg HDPE and Polypropylene drums) . The adhesive has excellent performance at low temperature. Compared to item Tire Label 5150 , there is no risk of the adhesive bleeding from the edges.

It can be produced as printed, and after it is produced, it can be printed with barcode printers using ribbon.

- Structure : Polypropylene Film

- Heat resistance: 70 0 C

- Total Thickness: 295 Micron

- Surface Weight: 100 gr/m2

- Surface Thickness: 138 Micron

- Adhesive Type : Very strong and heavy grammage sentetik rubber hotmelt

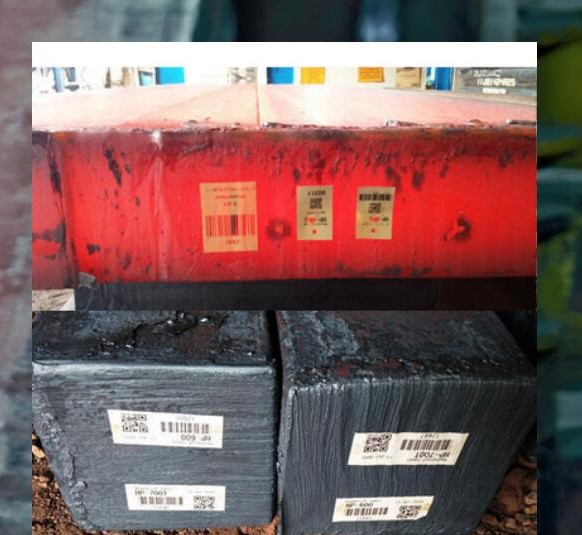

CONCRETE LABEL (5210)

5210 is a Matt white, bioriented top-coated polypropylene film, specially for labelling rough surfaces.

It is produced mainly for marking and identification of irregular metal surfaces . It is used for security identification labels for metal transport and adhesive labels for concrete surfaces .

Compatibility with resin based thermal transfer ribbons is good, giving good print definition and resistance to abrasion.

Liner is made of supercalendered glassine paper, havana colour, two sides siliconized.

Usual printing technologies, including letterpress, flexo, gravure and screen printing. Solvent, UV or water-based and thermal transfer.

Note: This product contains a very aggressive adhesive.

- Structure : HDPE Matte Film

- Temperature resistance: 70 0 C

- Total Thickness: 187 Micron

- Surface Weight: 80 gr/m2

- Surface Thickness: 105 Micron

- Adhesive Type : Permanent hotmelt

HDPE Matt Label (5250)

Top surface of 5250 Matte White HDPE (High Density Polyethylene) Film Label is specially coated for thermal transfer printing.

They are used in outdoor applications as a medium-life durable tracking label. Examples are chemical drum labels, wrapped pallet labels where stretching and recycling may be required.

Adhesive performance is high in applications where the surface is dirty, such as timber, stone, metal parts.

The absorbent topcoat provides a 'paper-like' surface. It is suitable for conventional printing methods and thermal transfer printing.

- Structure : Paper + PET + Paper

- Temperature resistance: 260 0 C

- Total Thickness: 265 Micron

- Surface Weight: 148 gr/m2

- Surface Thickness: 125 Micron

- Adhesive Type : Permanent rubber hotmelt

Ttp+PET+Ttp Label ( 5300 )

Thermal Transfer Paper + Polyester 5300 self adhesive labels are designed for use in the toughest applications such as outdoors, extreme temperatures, and environments where chemical interaction is common.

Ttp + PET 5300 is a self adhesive label used for identification purposed in the metal industry.

Labels for thermal transfer printers or manual annotation.

Material resistant to adverse weather conditions.

Labels for metals identification and traceability. We produce blank labels, in color or pre-printed with your logo and company information.

Good printing quality for barcodes and QR codes.

Wiperesistant printing. Labels in rolls

Material recommended for: Labels for steel cables, labels for pipes, reinforcing steel labels, rebar labels.