PP opaque barrel rubber label or polypropylene label is one of the group of plastic-based labels. It is produced in white color and is a label product that is extremely resistant to water, tearing and outdoor conditions. Opaque polypropylene does not stretch and does not tear easily as long as it is not forced. Because of these features, it is one of the types of labels that are suitable for use in outdoor environments, such as other plastic-based labels. It is long-lasting and also has a wide range of applications. They can be produced in printed form, and in addition, after they are produced, they can be printed with barcode printers using ribbon.

PP Opaque Tyre Label

PRODUCT CODE : 201034

PP OPAK FILM SELF ADHESIVE LABEL WITH TYRE ADHESIVE

Product

A white, glossy, biaxially oriented, cavitated, top-coated polypropylene film.

Use

For personal care and food labelling applications where resistance to water, oil and chemicals is important. Suitable for overprinting using thermal transfer

Typical technical values

Substance : 46 gr/m2 DIN 53352

Caliper : 61 µm DIN 53370

Tensile Strength : 70.0 n/mm2 DIN 53455

Opacity : % 80 DIN 53146/1

Gloss : % 90 DIN 67530/1

Printability : Suitable for flexography, screen, letterpress and offset print methods. Special inks designed for non-absorbent materials should be used. For UV printing, consult your ink supplier for ink recommendations. Thermal transfer is also possible with select ribbons.

Adhesive

Type : Tyre Hotmelt , Extra-strong permanent adhesive.

Composition : Rubber Hotmelt

Use : Tyre Labelling

The top surface is matte opaque, plastic-based, does not tear, is not affected by water and moisture. Ideal for outdoor applications. With resin ribbon printing, your barcode prints are resistant to friction and chemicals. You can prefer it for chemical product labelsi food product labels, address labels. It is produced with hotmelt and acrylic adhesive alternatives.

PP Opaque Matte Label

FACESTOCK CODE : 2011

POLYPROPYLENE PP MATT WHITE 80 MICRON

Product

A matt white, facestock, biaxially oriented, cavitated, top-coated polypropylene film

Typical technical values

Basis Weight : 58 gr/m2 DIN 53352

Caliper : 80 µm DIN 53370

Tensile Strength : 70.0 N/ mm2 DIN 53455

Opacity : % 80 DIN 53146/1

Applications and use

Applications are predominantly in market segments where rigid containers are used (e.g. Glass, PET). Due to fairly rigid nature of the film care should be taken with use on non-uniform surfaces and where a very high level of squeezability is desired .

Conversion & printing

Topcoating can be printed by conventional printing techniques including flexo, screen, offset, letterpress, silkscreen, gravure, and hot or cold foiling processes. UV, water-based and solvent-based inks can be used. The face material is suitable for Thermal Transfer printing

The top surface of the transparent label is PP film suitable for printing. It is produced with a transparent permanent acrylic adhesive. This adhesive is UV resistant and gives good results even on apolar surfaces. It is widely used on glass and plastic surfaces.

PP Transparent Label

PRODUCT CODE : 201513

PP CLEAR SELF ADHESIVE LABEL

A clear bi-axially oriented, polypropylene film with a print- receptive topcoat.

Basis Weight 52 g/m² ISO 536

Caliper 57 µm ISO 534

Adhesive

A general purpose permanent, acrylic based adhesive.

Liner

A white supercalendered glassine paper.

Basis Weight 79 g/m² ISO 536

Caliper 69 µm ISO 534

Adhesive Performance

Clear permanent adhesive featuring excellent UV resistance and weatherability together with

good adhesion performance, even on apolar substrates.

Applications and Use

Applications are predominantly in market segments where rigid containers are used (e.g. Glass, PET).

Conversion and Printing

The modified acrylic based topcoating can be printed by conventional printing techniques

including flexo, screen, offset, letterpress, silkscreen, gravure, and hot or cold foiling processes.

UV, water-based and solvent-based inks can be used. The topcoat is designed for optimal ink adhesion.

The face material is suitable for Thermal Transfer printing.

The top surface is glossy metallized PP film. The most common application areas; consist of product labels that require high attention such as hard surfaces such as glass and plastic, luxury consumer products such as beverages, cosmetics, personal care, and automotive oil drums. With acrylic adhesive.

PP Silver Label

FACESTOCK CODE : 2018

PP LIGHT TOP SILVER

A bright metallised bi-axially oriented, polypropylene film with a print-receptive topcoat

Facestock

Basis Weight 46 g/m² ISO 536

Caliper 51 µm ISO 534

Liner

White , supercalendered glassine paper.

Basis Weight 59 g/m² ISO 536

Caliper 53 µm ISO 534

Applications and Use

Applications are predominantly in market segments where rigid containers are

used (e.g. Glass, PET). Applications include luxury products such as spirits, home and personal

care, automotive lubricants, where eye catching high quality labels are required. Due to fairly

rigid nature of the film care should be taken with use on non-uniform surfaces and where a

very high level of squeezability is desired.

Conversion and Printing

The top coated metallised film can be printed by conventional printing techniques including

flexo, screen, offset, letterpress, silkscreen, gravure, and hot or cold foiling processes. UV, waterbased and solvent-based inks can be used. The topcoat is designed for optimum

ink adhesion. On-press corona treatment is not advised. The face material is suitable for

Thermal Transfer printing. Exact inks, foils and ribbons should be specified by your

ink/foil/ribbon supplier. The material has excellent register properties especially when

a high number of different colours are used.

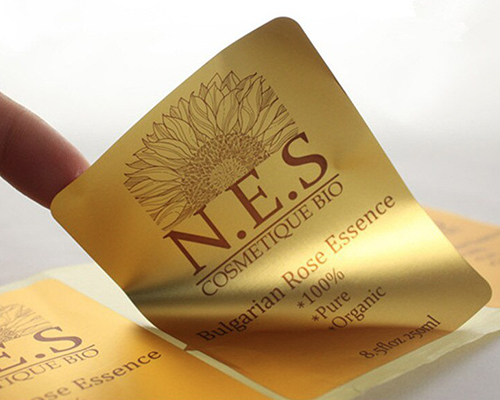

The top surface is glossy gold PP film. The most common application areas; consist of product labels that require high attention such as hard surfaces such as glass and plastic, luxury consumer products such as beverages, cosmetics, personal care, and automotive oil drums. With acrylic adhesive.

PP Gold Label

FACESTOCK CODE : 2019

PP LIGHT TOP GOLD

A bright gold bi-axially oriented, polypropylene film with a print-receptive topcoat

Facestock

Basis Weight 46 g/m² ISO 536

Caliper 51 µm ISO 534

Liner

White , supercalendered glassine paper.

Basis Weight 59 g/m² ISO 536

Caliper 53 µm ISO 534

Applications and Use

Applications are predominantly in market segments where rigid containers are

used (e.g. Glass, PET). Applications include luxury products such as spirits, home and personal

care, automotive lubricants, where eye catching high quality labels are required. Due to fairly

rigid nature of the film care should be taken with use on non-uniform surfaces and where a

very high level of squeezability is desired.

Conversion and Printing

The top coated metallised film can be printed by conventional printing techniques including

flexo, screen, offset, letterpress, silkscreen, gravure, and hot or cold foiling processes. UV, waterbased and solvent-based inks can be used. The topcoat is designed for optimum

ink adhesion. On-press corona treatment is not advised. The face material is suitable for

Thermal Transfer printing. Exact inks, foils and ribbons should be specified by your

ink/foil/ribbon supplier. The material has excellent register properties especially when

a high number of different colours are used.