PP opak varil lastik etiketi veya polipropilen etiket, plastik bazlı etiket grubundandır.Beyaz renkte üretilir ve suya, yırtılmaya ve dış ortam şartlarına karşı son derece dayanıklı bir etiket ürünüdür.Opak polipropilen, esnemez ve zorlanmadığı müddetçe kolay kolay yırtılmaz. Sahip olduğu bu özelliklerden dolayı diğer plastik bazlı etiketler gibi dış ortamlarda kullanıma uygun olan etiket çeşitlerinden biridir. Uzun ömürlüdür ve aynı zamanda kullanım alanları oldukça geniştir. Baskılı olarak üretilebilirler ve ayrıca, üretildikten sonra ribon kullanılarak barkod yazıcılar ile baskı alınabilir.

PP Opak Tyre Etiket

PRODUCT CODE : 201034

PP OPAK FILM SELF ADHESIVE LABEL WITH TYRE ADHESIVE

Product

A white, glossy, biaxially oriented, cavitated, top-coated polypropylene film.

Use

For personal care and food labelling applications where resistance to water, oil and chemicals is important. Suitable for overprinting using thermal transfer

Typical technical values

Substance : 46 gr/m2 DIN 53352

Caliper : 61 µm DIN 53370

Tensile Strength : 70.0 n/mm2 DIN 53455

Opacity : % 80 DIN 53146/1

Gloss : % 90 DIN 67530/1

Printability : Suitable for flexography, screen, letterpress and offset print methods. Special inks designed for non-absorbent materials should be used. For UV printing, consult your ink supplier for ink recommendations. Thermal transfer is also possible with select ribbons.

Adhesive

Type : Tyre Hotmelt , Extra-strong permanent adhesive.

Composition : Rubber Hotmelt

Use : Tyre Labelling

Üst yüzeyi mat opak, plastik bazlı olup yırtılmaz, su ve nemden etkilenmez. Dış ortamlarda kalacak uygulamalar için idealdir. Resin ribbon baskısı ile barkod baskılarınız sürtünmelere ve kimyasallara karşı dayanıklılık gösterir. Kimyevi ürün etiketleri, gıda ürün etiketleri, adres etiketleri için tercih edebilirsiniz. Hotmelt ve akrilik yapışkan alternatifleri ile üretilmektedir.

PP Opak Mat Etiket

FACESTOCK CODE : 2011

POLYPROPYLENE PP MATT WHITE 80 MICRON

Product

A matt white, facestock, biaxially oriented, cavitated, top-coated polypropylene film

Typical technical values

Basis Weight : 58 gr/m2 DIN 53352

Caliper : 80 µm DIN 53370

Tensile Strength : 70.0 N/ mm2 DIN 53455

Opacity : % 80 DIN 53146/1

Applications and use

Applications are predominantly in market segments where rigid containers are used (e.g. Glass, PET). Due to fairly rigid nature of the film care should be taken with use on non-uniform surfaces and where a very high level of squeezability is desired .

Conversion & printing

Topcoating can be printed by conventional printing techniques including flexo, screen, offset, letterpress, silkscreen, gravure, and hot or cold foiling processes. UV, water-based and solvent-based inks can be used. The face material is suitable for Thermal Transfer printing

Şeffaf etiketin üst yüzeyi baskıya uygun PP filmdir. Şeffaf permanent akrilik yapışkan ile üretilir. Bu yapışkan UV dayanımlıdır ve apolar yüzeylerde dahi iyi netice vermektedir. Cam ve plastik yüzeylerde yaygın olarak kullanılır.

PP Şeffaf Etiket

PRODUCT CODE : 201513

PP CLEAR SELF ADHESIVE LABEL

A clear bi-axially oriented, polypropylene film with a print- receptive topcoat.

Basis Weight 52 g/m² ISO 536

Caliper 57 µm ISO 534

Adhesive

A general purpose permanent, acrylic based adhesive.

Liner

A white supercalendered glassine paper.

Basis Weight 79 g/m² ISO 536

Caliper 69 µm ISO 534

Adhesive Performance

Clear permanent adhesive featuring excellent UV resistance and weatherability together with

good adhesion performance, even on apolar substrates.

Applications and Use

Applications are predominantly in market segments where rigid containers are used (e.g. Glass, PET).

Conversion and Printing

The modified acrylic based topcoating can be printed by conventional printing techniques

including flexo, screen, offset, letterpress, silkscreen, gravure, and hot or cold foiling processes.

UV, water-based and solvent-based inks can be used. The topcoat is designed for optimal ink adhesion.

The face material is suitable for Thermal Transfer printing.

Üst yüzeyi parlak metalize PP filmdir. En yaygın uygulama alanlarını ; cam ve plastic gibi sert yüzeyler , içecek , kozmetik , kişisel bakım gibi lüks tüketim ürünleri , otomotivde yağ bidonları gibi yüksek dikkkat çekicilik isteyen ürün etiketlemeleri oluşturur. Akrilik yapışkanlıdır.

PP Silver Etiket

FACESTOCK CODE : 2018

PP LIGHT TOP SILVER

A bright metallised bi-axially oriented, polypropylene film with a print-receptive topcoat

Facestock

Basis Weight 46 g/m² ISO 536

Caliper 51 µm ISO 534

Liner

White , supercalendered glassine paper.

Basis Weight 59 g/m² ISO 536

Caliper 53 µm ISO 534

Applications and Use

Applications are predominantly in market segments where rigid containers are

used (e.g. Glass, PET). Applications include luxury products such as spirits, home and personal

care, automotive lubricants, where eye catching high quality labels are required. Due to fairly

rigid nature of the film care should be taken with use on non-uniform surfaces and where a

very high level of squeezability is desired.

Conversion and Printing

The top coated metallised film can be printed by conventional printing techniques including

flexo, screen, offset, letterpress, silkscreen, gravure, and hot or cold foiling processes. UV, waterbased and solvent-based inks can be used. The topcoat is designed for optimum

ink adhesion. On-press corona treatment is not advised. The face material is suitable for

Thermal Transfer printing. Exact inks, foils and ribbons should be specified by your

ink/foil/ribbon supplier. The material has excellent register properties especially when

a high number of different colours are used.

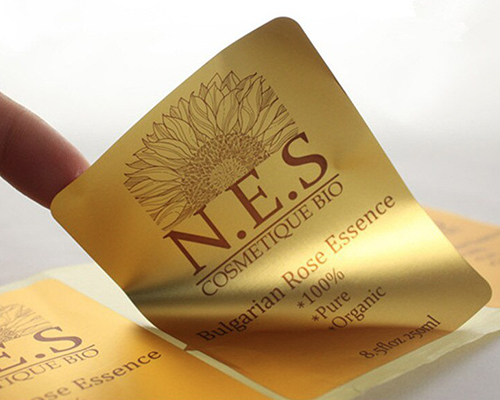

Üst yüzeyi parlak gold PP filmdir. En yaygın uygulama alanlarını ; cam ve plastic gibi sert yüzeyler , içecek , kozmetik , kişisel bakım gibi lüks tüketim ürünleri , otomotivde yağ bidonları gibi yüksek dikkat çekicilik isteyen ürün etiketlemeleri oluşturur. Akrilik yapışkanlıdır.

PP Gold Etiket

FACESTOCK CODE : 2019

PP LIGHT TOP GOLD

A bright gold bi-axially oriented, polypropylene film with a print-receptive topcoat

Facestock

Basis Weight 46 g/m² ISO 536

Caliper 51 µm ISO 534

Liner

White , supercalendered glassine paper.

Basis Weight 59 g/m² ISO 536

Caliper 53 µm ISO 534

Applications and Use

Applications are predominantly in market segments where rigid containers are

used (e.g. Glass, PET). Applications include luxury products such as spirits, home and personal

care, automotive lubricants, where eye catching high quality labels are required. Due to fairly

rigid nature of the film care should be taken with use on non-uniform surfaces and where a

very high level of squeezability is desired.

Conversion and Printing

The top coated metallised film can be printed by conventional printing techniques including

flexo, screen, offset, letterpress, silkscreen, gravure, and hot or cold foiling processes. UV, waterbased and solvent-based inks can be used. The topcoat is designed for optimum

ink adhesion. On-press corona treatment is not advised. The face material is suitable for

Thermal Transfer printing. Exact inks, foils and ribbons should be specified by your

ink/foil/ribbon supplier. The material has excellent register properties especially when

a high number of different colours are used.